Customized CNC Machining

customized metal processing service cnc machine spare parts 5 axis precision aluminum cnc milling machining parts

- Product ID: Customized CNC Machining

- Whatsapp:

- Phone: +8618998453346

- Tel: +8618998453346

- Email: [email protected]

- Time: 2023-08-14 23:01

- Price: 0

- FEEDBACK

Specification

Our Service

Secondary operations:

anodizing,painting,polishing, powder coating, sand blasting,Passivating,Laser engraving Oxide black,Electrophoretic black plating,and heat treatment.

Details Images

Aluminun parts、Stainless steel parts、Titanium parts

Anodize parts

Brass parts

Our Advantages

1.Small details make big difference.All the parts from our company have no sharp edge. All dimensions are controlled

according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit .

2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and

professional inspectors.

4. Each size of product must be tested one by one after completing production.

2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and

professional inspectors.

4. Each size of product must be tested one by one after completing production.

5.We have many years of export experience,exports to the US,Europe, Southeast Asia and other countries and regions.

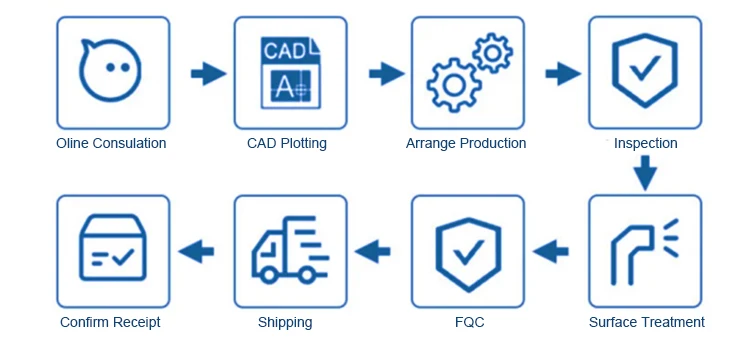

Production Process

If You Want To Create Something But No Ability To Design

You:I want to make a new product,but i only have hand made sketches,can anyone help me ?

Mogel:No worry at all.We have very

strong professional engineering and designing team,come to us,you will be in good hands.

strong professional engineering and designing team,come to us,you will be in good hands.

I Have No Idea What Shoud I Do To Bring My Idea Into A Real Product

You:This is my first time to create a new product,i have no idea what should i do to make it happen.

You:This is my first time to create a new product,i have no idea what should i do to make it happen.

Mogel:No worry at all.We will provide material suggestion and guide you through the design and cost evaluating stage,rest leave it

to us..

to us..

Company Profile

The factory was founded initially as a Plastic injection molding and tooling fabrication plant from2006, afterwards growing quickly and set up Mogel Industry Limited in HK, we have several divisions,focusing on turnkey solutions inclusive of the CNC machining, Punching, Stamping and assembly , Based on our extensive experience and deep understanding of mechanical and plastic components manufacturing,and now become a growing innovative mechanical , plastic components engineering design and manufacturing company.

Mogel group is proud to offer a comprehensive suite of compact and cost-effective products to our partners, monitoring and maintenance operations with the utmost in quality. Our factory are engaged in mechanical and plastic components manufacturing over 10 years with our goal to leverage on our synergetic capability to add value to our customer and grow the business together.

Mogel group is proud to offer a comprehensive suite of compact and cost-effective products to our partners, monitoring and maintenance operations with the utmost in quality. Our factory are engaged in mechanical and plastic components manufacturing over 10 years with our goal to leverage on our synergetic capability to add value to our customer and grow the business together.

Strict inspection we do during operation

1. Experienced QC testers to check the products dimension, surface and performance according to drawings specification.

2. Experienced IQC to check the dimensions and surface of the incoming material.

3. Experienced PQC to inspect full-course during the processing.

4. Experienced FQC to inspect all the plating products from outsides and make the 100% inspection before the shipments.

Quality sample will be provided for your testing before production according to ISO 9001: 2008.

We are pleased to service you with excellent quality, reasonable cost and grow withyou together.

1. Experienced QC testers to check the products dimension, surface and performance according to drawings specification.

2. Experienced IQC to check the dimensions and surface of the incoming material.

3. Experienced PQC to inspect full-course during the processing.

4. Experienced FQC to inspect all the plating products from outsides and make the 100% inspection before the shipments.

Quality sample will be provided for your testing before production according to ISO 9001: 2008.

We are pleased to service you with excellent quality, reasonable cost and grow withyou together.

FAQ

Q1.How to have my components quoted ?

A1: Please contact us via TradeManager or Email and send us your drawings inclusive of 2D and 3D (.STEP or .IGE file) and detail requirements. We are pleased to sign NDA with you if you prefer. Then our engineering team will work on them and submit competitive quotation to you.

Q2.What is the lead time for tooling and samples fabrication?

A2: The exact lead time depends on your parts specification.

The normal lead time is 40*45 days for tooling fabrication and samples.

If the tooling is not required, the lead time for samples is 15 days normally.

Q3.Can I have prototypes for testing before tooling ?

A3: Yes, our factory have team to support prototypes with machining process to fabricate them for your testing.

Q4.How to ship the samples and production order ?

A4: We will normally ship samples via DHL, UPS or FedEX via our cooperated forwarder or freight collect. For the shipping of production order, it will be by sea or by air

Q5.How to ensure the quality of parts?

A5: Firstly, our team will inspect all incoming material. QC team will inspect parts while production and finished products, then submit Quality Inspection Report together with samples and production order.

A1: Please contact us via TradeManager or Email and send us your drawings inclusive of 2D and 3D (.STEP or .IGE file) and detail requirements. We are pleased to sign NDA with you if you prefer. Then our engineering team will work on them and submit competitive quotation to you.

Q2.What is the lead time for tooling and samples fabrication?

A2: The exact lead time depends on your parts specification.

The normal lead time is 40*45 days for tooling fabrication and samples.

If the tooling is not required, the lead time for samples is 15 days normally.

Q3.Can I have prototypes for testing before tooling ?

A3: Yes, our factory have team to support prototypes with machining process to fabricate them for your testing.

Q4.How to ship the samples and production order ?

A4: We will normally ship samples via DHL, UPS or FedEX via our cooperated forwarder or freight collect. For the shipping of production order, it will be by sea or by air

Q5.How to ensure the quality of parts?

A5: Firstly, our team will inspect all incoming material. QC team will inspect parts while production and finished products, then submit Quality Inspection Report together with samples and production order.

CATEGORIES

LATEST NEWS

CONTACT US

Whatsapp:

Phone: +8618998453346

Tel: +8618998453346

Email: [email protected]

Addr: Guangdong Province, China TianHe District, GuangZhou Num 888